Our Material Collection

We reimagine waste as a valuable resource for creating timeless design objects. The materials we use come from various waste sources, including recycled plastics from post-consumer and industrial waste, as well as bio-based plastics made from plant by-products. We focus on creating high-quality, durable 3D-printed products while embracing circular approaches to material sourcing.

Bio-based Plastic

Bio-based plastics are made—either wholly or partially—from polymers derived from organic sources. These resources are typically obtained from starchy plants. The sugar in these renewable materials are fermented and turned into lactic acid, which transforms to polylactic acid (PLA). While bio-based plastics reduce reliance on fossil resources, it is crucial to ensure that the materials used do not compete with food production. Additionally, it is important that the biomass removed from the land is not compensated with synthetic fertilisers. At ENGA, we are committed to using materials with the least possible environmental impact. The bio-based plastic used in our products is derived from sugarcane, potato, or corn starch and is either mixed with 1% colour pigments or up to 50% natural fibres.

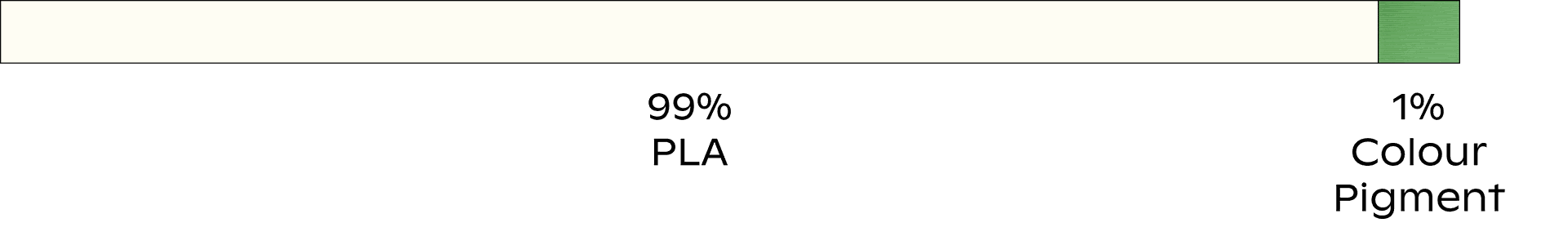

Colour Pigment

By adding 1% colour pigments to the bio-based plastic (PLA) we get different colour variations.

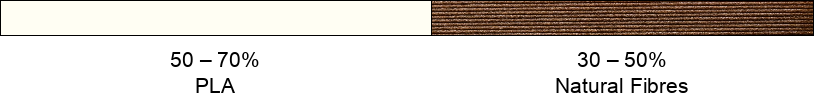

Natural Fibres

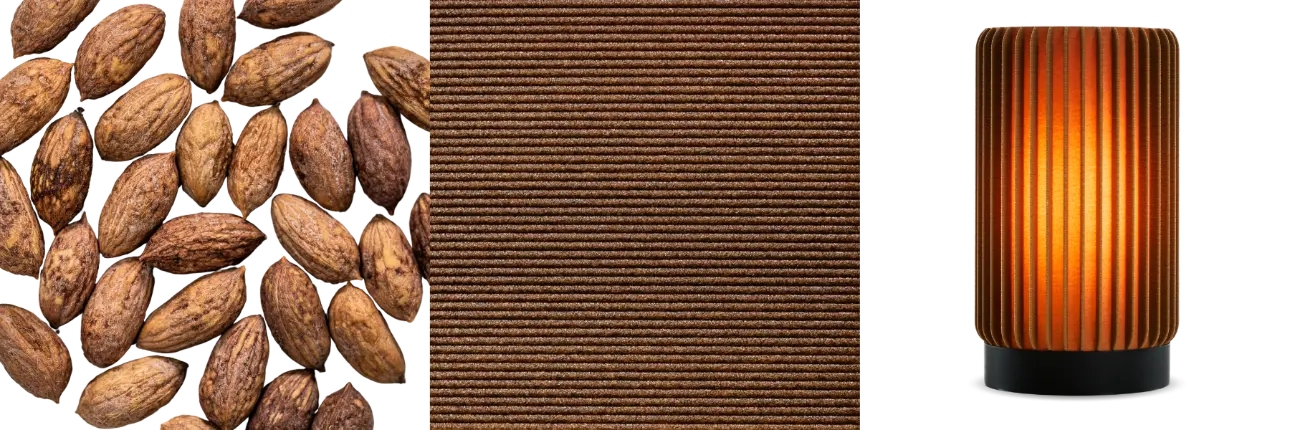

Natural fibres can be added to bio-based plastic to enhance its structural strength. This not only changes the look and touch of the surface but also reduces the use of plastic. Similar to the resources used for bio-based plastics, it is important that the natural fibres are not grown solely for this purpose. Using natural fibres in combination with PLA makes sense only if they come from waste streams, such as olive pits or sawdust from wood or cork.

Olive Pits

Cork Bark

Pine Wood

Wenge Wood

Want to learn more about bio-based materials?

Recycled Plastic

By using recycled plastics, we extend the life of a material that is often burned for energy production after just a short use. Instead of burning plastic waste after its first use, we keep it in the loop for as long as possible, only recycling its energy through burning when it no longer holds technical value. By giving plastic an extended life, we reduce the need for new materials and the extraction of additional raw resources.

Recycled Polyethylene terephtalate (PET)

Recycled PET (rPET) is plastic made from recycled polyethylene terephthalate, commonly used in bottles and packaging. It is recycled and processed to a 3D printing filament in Spain.

Post-Consumer Polypropylene (PP)

PP collected from post-consumer waste in Switzerland.

In partnership with Kunststoffsammelsack.ch

Want to learn more about recycled materials?

An efficient recycling process

ENGA with it partners offers solutions for a fully closed and circular plastic cycle in Switzerland. Thanks to the post consumer plastic waste collection system, we are able to generate high added value products from plastic waste and replace the use of virgin material.

We have optimised our recycling process to be efficient, minimising unnecessary steps and shortening transportation distances for a more eco-friendly approach.

Collection

Post-consumer plastic, sourced from items like bottles and packaging, is collected after use to reduce waste, conserve resources, and support the circular economy. Recycling it minimises the reliance on new plastics.

Recycling

The waste undergoes the process of shredding, cleaning, and sorting into different materials to facilitate recycling and increase the final quality.

Circular Design

We design and manufacture products using reused materials, with a focus on ensuring they are repairable, dismountable, and ultimately recyclable at the end of their life cycle.

3D Printing

Additive manufacturing enables local production, allowing us to manufacture only on demand and thereby eliminate overproduction and material waste.